Specialty Inspection Equipment & Advanced Field Technology

Delivering accurate, defensible inspection results requires more than experience alone. We invest in advanced specialty inspection equipment to provide precise measurements, high-resolution imaging, and data you can trust on critical industrial and energy projects.

By combining expert inspectors with cutting-edge technology, you can detect issues that traditional visual inspections can miss, reduce uncertainty, and create permanent digital records of field conditions.

High-Definition 3D Laser Scanning

FARO Focus Premium 200m Laser Scanner

3D laser scanning capability captures millions of measurement points per second to create highly accurate digital models of structures and components.

This technology is used for:

- As-built verification of foundations, anchor bolts, and structural elements

- Dimensional checks for tower sections, flanges, and large assemblies

- Deformation and settlement monitoring

- Clash detection and fit-up validation before installation

The result is a precise, shareable point cloud that allows owners, engineers, and contractors to review exact field conditions from anywhere, reducing rework and disputes

Digital Radiography (DR)

HPX-DRX Digital Radiography Panel

Digital radiography provides immediate, high-resolution internal images without the delays of traditional film processing.

Applications include:

- Weld quality evaluation

- Detection of internal defects such as cracks, lack of fusion, and porosity

- Inspection of critical structural and pressure-retaining components

Instant image availability speeds decision-making, while permanent digital records support quality documentation and traceability.

Automated and Remote Ultrasonic Scanning

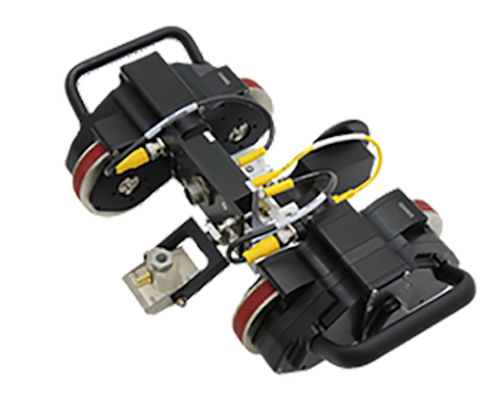

Scantech X3 Crawler Systems

These remotely operated ultrasonic crawlers perform encoded, repeatable scans of welds and surfaces, even in difficult or hazardous locations.

Key benefits:

- Consistent, high-quality data independent of operator hand motion

- Ability to scan long weld seams and large surfaces efficiently

- Reduced need for scaffolding or confined space entry

- Permanent, reviewable scan data for future reference

Ideal for tower welds, structural joints, and heavy industrial components where reliability is critical.

Positive Material Identification (PMI)

Olympus XRF Analyzer

Our handheld X-ray fluorescence (XRF) analyzer instantly verifies material chemistry in the field.

This enables:

- Positive material identification of steels and alloys

- Verification of correct materials before installation

- Detection of mixed or incorrect grades that could lead to failures

Fast, non-destructive testing helps prevent costly material mix-ups and ensures compliance with engineering specifications.

Data-Driven Quality Assurance

All specialty inspections generate digital, traceable data sets that can be integrated into your project quality documentation, including:

- Georeferenced 3D scan files

- High-resolution radiographic images

- Encoded ultrasonic scan maps and reports

- Material composition certificates from XRF testing

These records provide objective evidence of quality, support turnover and warranty requirements, and create a valuable baseline for future maintenance and inspections.

Safer, Faster, More Accurate Inspections

Advanced equipment allows us to:

- Minimize intrusive or destructive testing

- Reduce time spent at height or in hazardous areas

- Increase inspection coverage and repeatability

- Deliver clear, defensible results to owners and engineers

By leveraging state-of-the-art inspection technology, we move beyond simple visual checks to deliver measurable, verifiable quality on every project.

Technology That Protects Your Investment

From 3D laser scanning and digital radiography to automated ultrasonic testing and real-time material verification, our specialty inspection tools ensure that critical components are built and installed exactly as intended.

The result is better decisions in the field, fewer surprises during commissioning, and long-term confidence in the assets you build.